The oil and gas industry is changing for the better, thanks to disruptive IoT technology. From real-time vehicle tracking, offshore monitoring, and reliable geofencing to tanker weight management, reduced carbon footprint, and smoother supply chain management — the oil and gas companies are benefiting from IoT like never before. The article gives an overview of 14 IoT apps in the industry in detail. Let us have a look now:

The Industrial Internet of Things (IIoT) involves the use of connected devices, advanced software, and sensor-based tools in sync with industrial machinery. These systems communicate amongst themselves to perform industrial-scale functions with limited human involvement.

This disruptive technology is transforming industries by automating and streamlining processes. As a result, the IIoT market is growing exponentially. Here are a few statistics and predictions related to it:

- The global market size of IIoT is expected to grow at a CAGR of 29.4% between 2019-2025 and is estimated to be worth USD 949.42 billion by the end of it.

- The “total number of IoT connections ” is predicted to be around 83 billion by 2024.

- IIoT is slated to be among the leading IoT market segments.

- COVID-19 pandemic accelerated adoption of IoT, and around 90% of organizations say it is critical for their success.

IIOT: The future of the oil and gas industry

Although the said industry has been in operation for ages, it also has to handle multiple issues — ranging from inefficient processes and improper resource utilization to safety omissions and demand fluctuations.

Many of these challenges are attributed mainly to the traditional and inefficient approach that many oil and gas companies take for data collection and asset management.

Adopting this technology gives respite to such businesses as they can streamline crucial business processes such as inventory management, IoT in supply chain management, change analytics, fleet monitoring, and exploration opportunities.

Using real-time data, for instance, helps refineries avoid accidents and minimize downtime with preventive maintenance.

Are You Ready to Transform Your Oil & Gas Fleet with IoT Integration?

Talk to Our IoT ExpertsIIoT applications revolutionizing oil and gas

The companies operating in this sector implement Industry 4.0 technologies such as IoT, data-powered analytics, and robotics for automating and optimizing their processes. IIoT also helps them enhance operational efficiency and reduce costs by 10 to 20%. Here are 14 ways in which the technology is spearheading the revolution:

1. Real-time vehicle tracking and route management

Oil and gas companies are implementing IoT for fleet management and route optimization. The technology is mainly valuable for providing them control over the movement of their tankers through real-time tracking.

They use the data to ensure the tankers reach their destination on time and through the specified (usually the shortest) route only.

In addition, sensor-based devices offer reports of vehicle condition, driver behavior, idle time, and even cargo health status. Proper monitoring and preventive maintenance of vehicles can be done using this data.

2. Avante-garde data collection system

Sensor-based tools and connected devices work together to provide real-time data for all processes. For starters, equipment performance and inventory levels can be easily tracked through digital dashboards.

Acoustic monitoring systems ensure simultaneous quality management while maintaining the flow rate of oil. In addition, real-time data available through these advanced systems minimizes downtime and enables continuous process flow.

The data is stored in cloud-based data centers for easy sharing and retrieval within the oil and gas companies. Digital representation through historical comparisons and data analytics ensures informed decision-making.

3. Straight off pipeline monitoring

Leakages in oil pumping pipelines are a significant concern, leading to forced downtime, loss of inventory, and inevitable expenses. Manual monitoring is utilized in oil and gas companies to avoid these damages, but it is not as efficient as real-time IoT monitoring.

Real-time data helps in detecting abnormalities in equipment and saves precious human labor. It can even raise the alarm depending on the health and age of pipes, filters, and motors to avoid any accidents, resulting in any loss of life or grave injuries.

Companies leveraging IIoT development can efficiently manage their assets and employees by optimizing their performance and keeping them safe in the long run.

4. Reliable geofencing

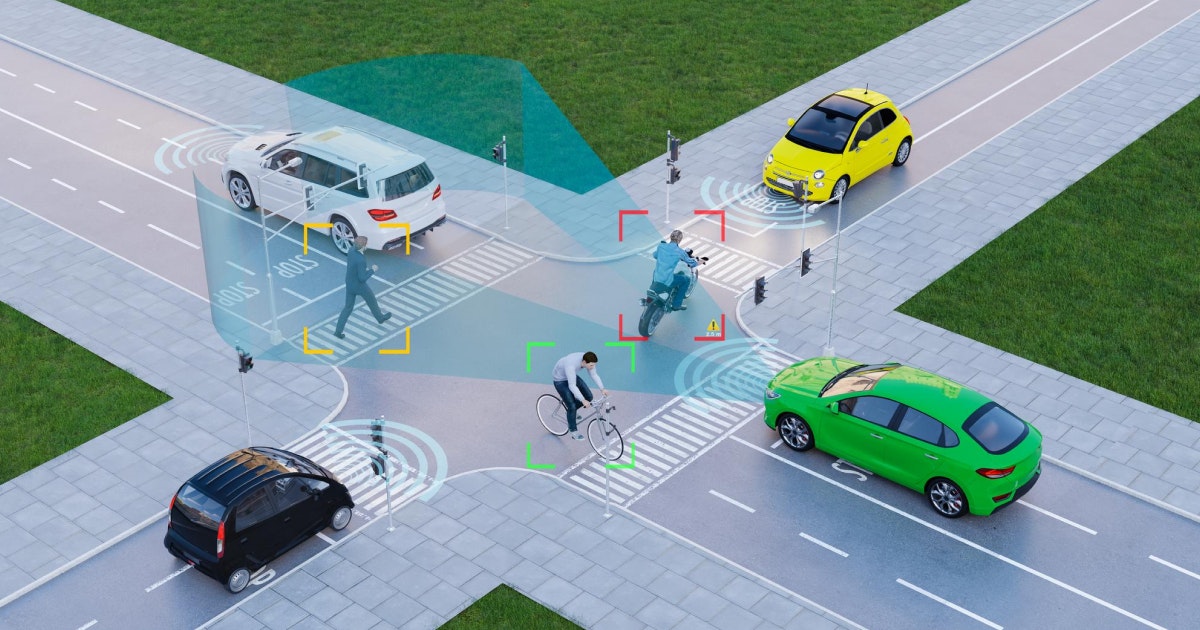

Oil and gas IoT app development offers geo-fencing for effective fleet management. Setting routes and boundaries for each vehicle minimizes misuse of tankers, fuel, and driver time.

Advanced GPS tracking systems, for instance, monitor the movement of all connected vehicles and share real-time updates with the drivers on the road.

Oil and gas companies implementing the geofencing technology can enjoy benefits such as added safety, on-schedule delivery, and smooth on-field communication, and reduce chances of vehicle theft/misuse.

5. Excellent tanker weight management

Oil cargo density may change with temperature fluctuations, resulting in changes in the weight of the tanker. Tanker weight management software detects changes in tanker weight and alerts the driver. The IoT-based real-time weight measurement system helps avoid accidents and overweight (and expensive) penalties.

6. Fail-proof offshore monitoring

Oil and gas rigs have extreme temperature and pressure conditions. Therefore, it makes equipment and process monitoring difficult and expensive for the companies. In such a case, low-power WAN (LPWAN) offers effective machine-to-machine (M2M) wireless connectivity.

These battery-powered detectors effectively monitor the offshore oil and gas rigs and oil wells. They provide real-time information that is useful in sending alerts in case of leakages. This information can also be used for remote oil extraction processes, making them safer and cost-efficient when compared to traditional methods.

7. Better refinery monitoring

Monitoring an oil and gas refinery manually is an exhaustive process. Using IIoT-powered systems helps convenient and adequate monitoring of the entire infrastructure of the refinery.

Real-time data collection and utilization helps in the precise handling of all equipment. Sensors can be fitted on points that are inaccessible to humans, and crucial data can be safely collected for better management of the refinery.

8. Decreased safety risk

Exploring oil and gas sites by manually visiting them is hazardous for the employees of oil and gas companies. Accidents due to the unavailability of enough information may prove fatal to workers and lead to a loss for the companies.

IIoT solutions help in remote monitoring of the sites for safety purposes. Decentralized control systems and automation devices can even facilitate unmanned operations in risk-prone areas.

9. Efficient cargo monitoring

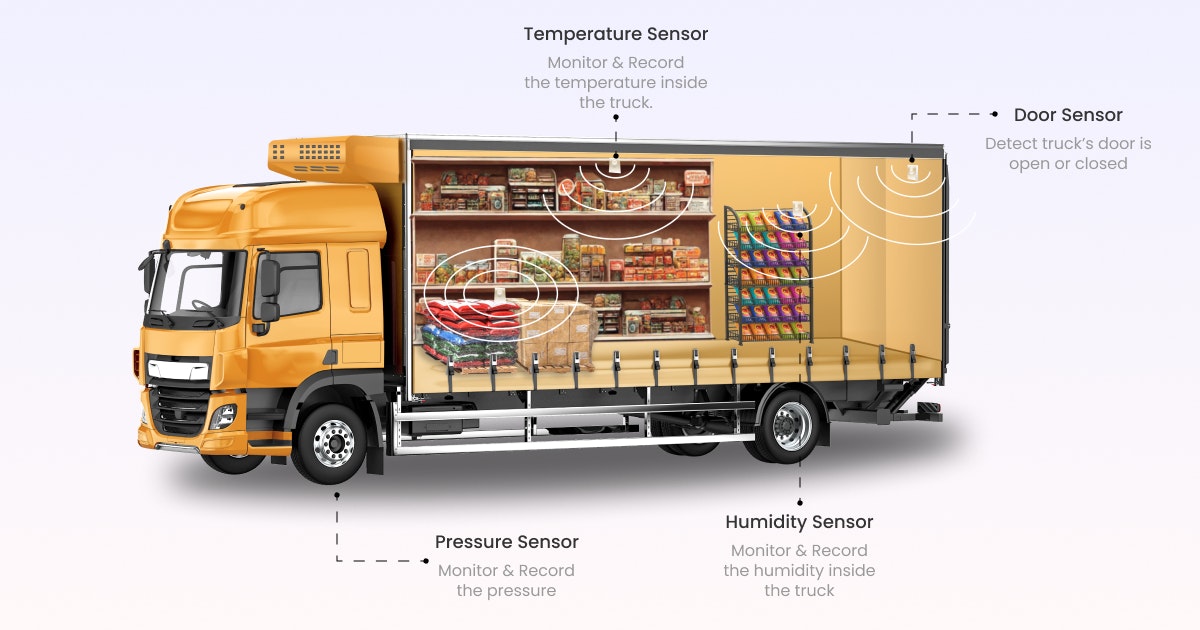

Shipping oil and gas cargo involves the risk of fluctuations in temperature and pressure, which may lead to changes in density and properties of the load. IIoT-powered solutions help in monitoring the status and tracking the location of the cargo.

Sensors and gauges help remotely maintain the prescribed settings for safe cargo shipping. GPS trackers help monitor the route and location to ensure timely delivery of the shipment — without any loss of commodity or mishaps.

Similarly, smart fleet management systems can be used to monitor driver activities and deterioration in the condition of vehicles. Human life is important. IIoT helps companies preserve and safeguard their employees’ lives.

Revolutionize your industry with Industrial IoT. Contact us now!

Let's Connect10. Controlled environmental footprint

The oil and gas industry adversely impacts the environment. For example, oil spills cause water and air pollution. In addition, the sounds, emissions, and lights produced by the oil and gas sites disrupt the wildlife habitat in the region.

Adopting IoT can reduce the carbon footprint of oil and gas companies. It can help avoid hazardous oil spills, reduce the need for exploratory drilling and unnecessary travel.

In this day and age, when environment preservation is such a massive concern worldwide, IoT gives oil and gas companies a medium to reduce the damage.

11. Smooth supply chain management

Storing and managing oil and gas inventory is challenging. However, sensors can trace the quality of crude oil and store it after segmentation based on crude configuration. This was not possible traditionally speaking.

IIoT-driven systems help track the location of inventory, keep a count of the barrels in each segment, and schedule processing. They also help streamline the business operations and make supply chain management convenient for refineries.

12. Seismic exploration sensors

Mapping subsurface drilling sites can optimize the process of oil exploration. Deploying IoT sensors at drilling locations helps discover new sites for rigging and improves the output of operational ones effectively.

Seismic waves are sent into the Earth, and as they return after reflecting off a rock, they are captured by a network of seismic sensors, also known as Geophones.

The data collected by them is transferred to remote servers over the internet and is processed to provide an image of the site. Thus, comparative data analysis facilitates the identification of the best drilling site and enhances the effectiveness of the extraction process.

This sensor-based system improves productivity while saving them the time and cost required for site selection. The decision-making process is also shorter and less tedious.

13. Predictive maintenance of operations

Maintenance operations in the oil and gas industry can be optimized by using digital replicas of assets. These replicas of physical equipment predict maintenance issues. The preventive repair can help extend asset life and save costs by minimizing downtime.

The insights gained from a comparative study of historical performance data help restructure operational processes and improve asset designs.

14. Massive fuel data management

Oil and gas companies have huge amounts of data related to their supply chain and business processes. IIoT-driven systems are capable of gathering, storing, and organizing the data securely so that the companies can make sense of them rapidly and efficiently.

Fuel station management apps using sensors ensure fuel levels in tanks are maintained and flow through pipes is consistent. Historical data analysis helps in operational forecasting for delivery scheduling and process optimization.

Top 4 IoT solutions positively impacting the oil and gas industry

1. Supervisory Control and Data Acquisition (SCADA)

Oil and gas companies can leverage the SCADA architecture comprising Programmable Logic Controllers (PLCs) or Remote Terminal Units (RTUs). It offers control over the processes of the industry through local and remote connectivity. The system gathers real-time data from sensors installed in pipes, valves, pumps, motors, and tanks.

2. Codovia

Codovia is an IIoT solutions provider for the oil and gas industry. They help businesses collect data by embedding factory equipment with sensors and smart devices connected over an internet network.

Companies that use Codovia for industrial automation of operational processes can remotely control their industrial machinery relatively easily. Their cloud-based solutions can be accessed over the web through customized mobile applications.

3. ThingsConnect

ThingsConnect offers an IoT gateway, which is an on-demand array of smart devices to enable quick and easy IoT connections in the oil and gas industries. Their open-source technology supports RFID and Bluetooth to offer total control of the system. This cloud-based system can be controlled through a custom application.

4. FourC

Catering to the evolving technology needs of the oil and gas industry, FourC offers Groovy M2M and IoT cloud systems. This distributed software platform supports industrial-scale M2M for oil and gas companies.

The FourC Groovy M2M Cloud System allows seamless remote management of industrial equipment through specialized software applications. All FourC software solutions are built to meet the NORSOK standard for SAS (Safety and Automation Systems) in the oil and gas industry.

Easing the task of managing fuel purchases

A fuel station management app built by Intuz helped SGC Africa keep track of the massive data management of fuel consumption. Our IoT-powered solution automated the real-time coordination of data across all fuel stations of the company.

It also helped SGC Africa track fuel consumption and the drivers’ delivery checkpoints to reduce the chances of fuel theft. For instance, every time their drivers refuel at the gas station, our app would immediately consolidate and communicate the data to SGC.

It gave a sneak peek into the total fuel consumed, the number of times a driver refueled, and the amount spent on refueling.

The future of the oil and gas industry

The said industry is transforming compellingly with the deployment of IoT technologies. Companies integrating IIoT solutions in the oil and gas industry are predicted to recover costs within three years of implementation of such advanced technologies.

Interestingly, the much-needed disruption in the oil and gas industry has been accelerated by the pandemic. As a result, the companies have fast-tracked IIoT adoption to join the long list of Industry 4.0 use cases and adapt their business for the upcoming era.

They can scale up or cut back on their resources depending on their operational integrity and bottom line. In addition, they can quickly adapt to trends like Energy Transition and ensure rapid facilitation of mergers and acquisitions.

More importantly, IoT can help oil and gas companies to implement best practice processes by significantly reducing manual labor and ensuring access to real-time global insights and cross-departmental collaboration.

Revolutionize Your Oil & Gas Operations with an IoT Fleet Management Application!

Explore ServicesIn conclusion

As IoT-powered applications for the oil and gas industry continue to proliferate, many software development firms are also pulling up their socks to create multi-level fleet management systems to minimize all the challenges that the companies face.

In addition, a reduction in the pricing of IoT tools and platforms has made them relatively affordable for oil and gas businesses — regardless of their budgets. So if you are looking for help in IoT product development, you have come to the right place.

Our expert IoT developers have immense experience in creating IoT apps for oil and gas companies. So please give us a holler today!